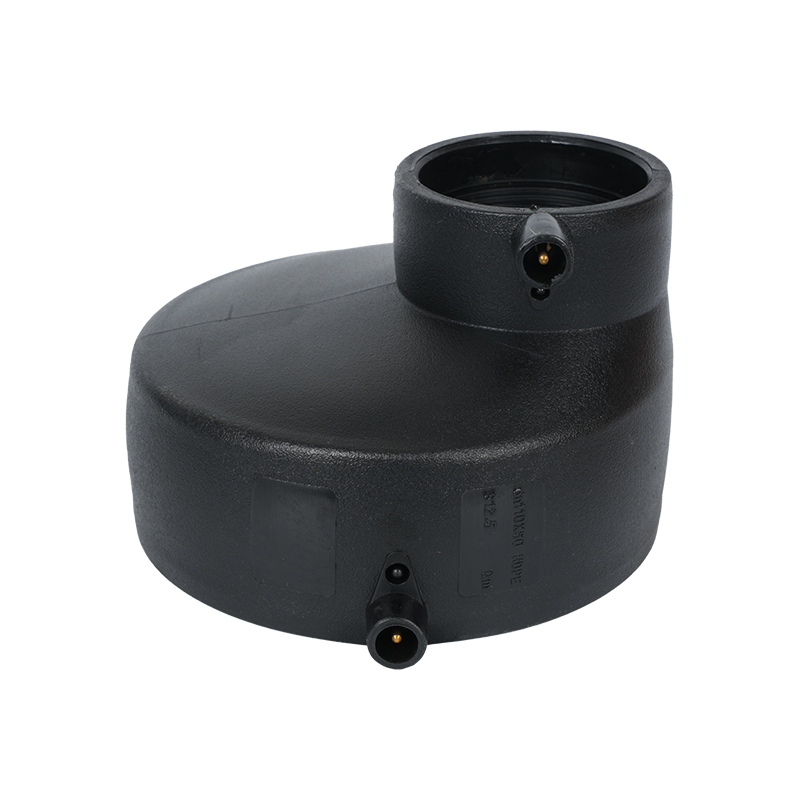

HDPE Electrofusion Stub End

HDPE Electrofusion Stub End is a high-performance polyethylene pipe connector that is widely used in urban water supply, drainage, gas transportation and other fields. HDPE Electrofusion Stub End has corrosion resistance and can resist the erosion of various chemical substances, maintaining the stability and safety of the pipeline system for a long time. It is made of environmentally friendly materials, non-toxic and odorless, and will not cause pollution to the environment. At the same time, due to its corrosion resistance, it reduces the frequency of maintenance and replacement of pipeline systems, reducing resource consumption and waste generation.

Technical Characteristics

HDPE Electrofusion Stub End also has better anti-aging properties and can maintain a long service life even under harsh environmental conditions. It uses advanced electrofusion connection technology to melt the connection parts through current heating to form an integrated connection structure. This connection method not only has high strength and good sealing performance, but also is easy and quick to install, greatly improving construction efficiency.

This product has good flexibility and impact resistance, can adapt to various complex terrain and climate conditions, and ensures the stable operation of the pipeline system. Its main material is high-density polyethylene (HDPE), which has better pressure resistance and can withstand large pressure changes.

Specifications

| SDR11 | ||||||

| SPECIFICATION | SIZE(mm) | |||||

| A | B | C | D | E | F | |

| 50 | 59 | 50 | 72 | 50 | 80 | 4.6 |

| 63 | 74.4 | 63 | 72 | 50 | 80 | 5.7 |

| 75 | 86.6 | 75 | 72 | 50 | 80 | 6.8 |

| 90 | 106.2 | 90 | 80 | 50 | 85 | 8.1 |

| 110 | 130 | 110 | 93 | 63 | 98 | 10 |

| 125 | 147 | 125 | 102 | 107 | 112 | 11.3 |

| 160 | 189 | 160 | 115 | 65 | 122 | 14.5 |

| 200 | 236 | 200 | 115 | 65 | 123 | 16.18 |

| 225 | 266 | 225 | 115 | 71 | 123 | 20.5 |

| 250 | 295 | 250 | 135 | 70 | 145 | 22.7 |

| 315 | 358 | 315 | 143 | 96 | 155 | 21.5 |

| SDR17 | ||||||

| SPECIFICATION | SIZE(mm) | |||||

| A | B | C | D | E | F | |

| 355 | 396 | 355 | 143 | 96 | 155 | 20.8 |

| 400 | 447 | 400 | 143 | 96 | 155 | 23.5 |

| 500 | 550 | 500 | 170 | 120 | 190 | 25 |

| 630 | 682 | 630 | 193 | 120 | 203 | 26 |

| 710 | 775 | 710 | 230 | 130 | 245 | 32.5 |

| 800 | 875 | 800 | 235 | 148 | 260 | 37.5 |

| 1000 | 1094 | 1000 | 330 | 180 | 350 | 45 |

-

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building drainage systems. Their corrosion resistance, lightweight nature, high strength, and long service life make them ideal for rainwater, w...

READ MORE -

HDPE (High-Density Polyethylene) threaded fittings are widely used in water supply, drainage, gas, and chemical industries due to their excellent corrosion resistance, wear resistance, and toughness. ...

READ MORE

KEEP IN TOUCH