HDPE Electrofusion Reducing Coupler

HDPE Electrofusion Reducing Coupler is a commonly used high-density polyethylene (HDPE) pipe connector that uses electrofusion technology to connect two pipes of different diameters by heating and melting the pipe ports to form a smooth, seamless seam connection.

Technical Characteristics

HDPE Electrofusion Reducing Coupler is made of high-density polyethylene material with better tensile strength and corrosion resistance. High-density polyethylene material has good chemical resistance and can withstand the erosion of various chemicals, ensuring the safe operation of the pipeline system. At the same time, its high strength characteristics can also withstand greater pressure, ensuring the stability and reliability of the pipeline.

HDPE Electrofusion Reducing Coupler uses hot-melt joining technology to fuse the pipe ports with the joints by heating and melting them. This connection method has good sealing and strength, and can effectively prevent pipe leakage and leakage. Compared with traditional glue connection methods, hot melt connections are stronger and more reliable, and can maintain stable connections in harsh working environments.

The inner wall of HDPE Electrofusion Reducing Coupler is very smooth, which reduces fluid resistance and sediment accumulation, and improves the flow and transportation efficiency of the pipeline. At the same time, the smooth inner wall can also reduce the growth of bacteria and microorganisms and keep the water clean and hygienic. This is very important for the transportation of liquids and gases and ensures the normal operation of the pipeline system.

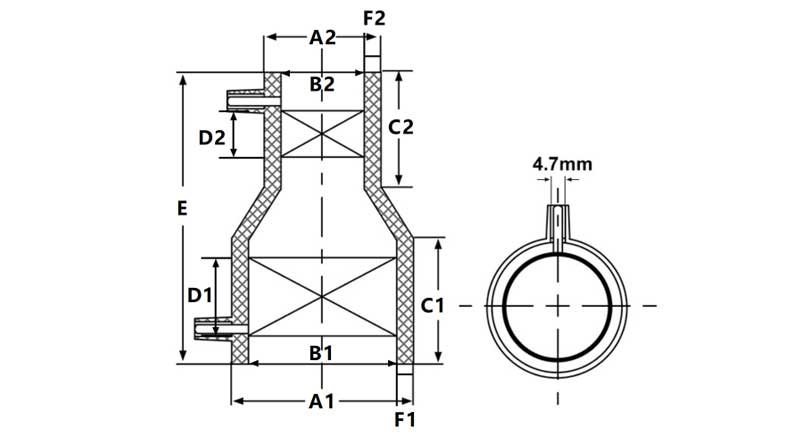

Specifications

| SDR17 | |||||||||||

| SPECIFICATION | S I Z E ( m m ) | ||||||||||

| A1 | A2 | B1 | B2 | C1 | C2 | D1 | D2 | E | F1 | F2 | |

| 63x50 | 74 | 59 | 63 | 50 | 54 | 50 | 30 | 30 | 110 | 5.7 | 4.5 |

| 75x50 | 88 | 63 | 75 | 50 | 57 | 50 | 30 | 30 | 120 | 6.8 | 4.5 |

| 75x63 | 88 | 74 | 75 | 63 | 57 | 50 | 30 | 30 | 120 | 6.8 | 5.7 |

| 90x50 | 106 | 59 | 90 | 50 | 64 | 50 | 30 | 30 | 130 | 8.1 | 4.5 |

| 90x63 | 106 | 74 | 90 | 63 | 64 | 50 | 30 | 30 | 130 | 8.1 | 5.7 |

| 90x75 | 106 | 88 | 90 | 75 | 64 | 50 | 40 | 35 | 130 | 8.1 | 6.8 |

| 110x50 | 130 | 59 | 110 | 50 | 72 | 60 | 40 | 35 | 144 | 10 | 4.5 |

| 110x63 | 130 | 74 | 110 | 63 | 72 | 60 | 40 | 35 | 144 | 10 | 5.7 |

| 110x75 | 130 | 88 | 110 | 75 | 72 | 60 | 40 | 35 | 144 | 10 | 6.8 |

| 110x90 | 130 | 106 | 110 | 90 | 72 | 60 | 40 | 35 | 144 | 10 | 8.1 |

| 160x63 | 189 | 74 | 160 | 63 | 85 | 95 | 40 | 65 | 205 | 14.5 | 5.7 |

| 160x75 | 189 | 88 | 160 | 75 | 85 | 75 | 40 | 40 | 180 | 14.5 | 6.8 |

| 160x90 | 189 | 106 | 160 | 90 | 85 | 75 | 40 | 40 | 180 | 14.5 | 8.1 |

| 160x110 | 189 | 130 | 160 | 110 | 85 | 75 | 40 | 47 | 177 | 14.5 | 10 |

| 160x125 | 189 | 148 | 160 | 125 | 83 | 83 | 43 | 43 | 176 | 14.5 | 11.5 |

| 200x63 | 236 | 74 | 200 | 63 | 95 | 105 | 40 | 70 | 230 | 18.1 | 5.7 |

| 200x75 | 236 | 89 | 200 | 75 | 95 | 95 | 40 | 75 | 220 | 18.18 | 6.81 |

| 200x90 | 236 | 106 | 200 | 90 | 95 | 95 | 50 | 40 | 220 | 18.18 | 8.18 |

| 200x110 | 236 | 130 | 200 | 110 | 95 | 85 | 50 | 40 | 195 | 18.18 | 10 |

| 200x125 | 236 | 148 | 200 | 125 | 95 | 81 | 46 | 40 | 206 | 18.18 | 11.5 |

| 200x160 | 236 | 189 | 200 | 160 | 95 | 85 | 50 | 40 | 195 | 18.18 | 14.54 |

| 250x110 | 296 | 130 | 250 | 110 | 107 | 85 | 57 | 50 | 232 | 23 | 10 |

| 250x160 | 296 | 189 | 250 | 160 | 107 | 85 | 57 | 50 | 232 | 23 | 14.54 |

| 250x200 | 296 | 236 | 250 | 200 | 107 | 85 | 57 | 50 | 232 | 23 | 23.6 |

-

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building drainage systems. Their corrosion resistance, lightweight nature, high strength, and long service life make them ideal for rainwater, w...

READ MORE -

HDPE (High-Density Polyethylene) threaded fittings are widely used in water supply, drainage, gas, and chemical industries due to their excellent corrosion resistance, wear resistance, and toughness. ...

READ MORE

KEEP IN TOUCH