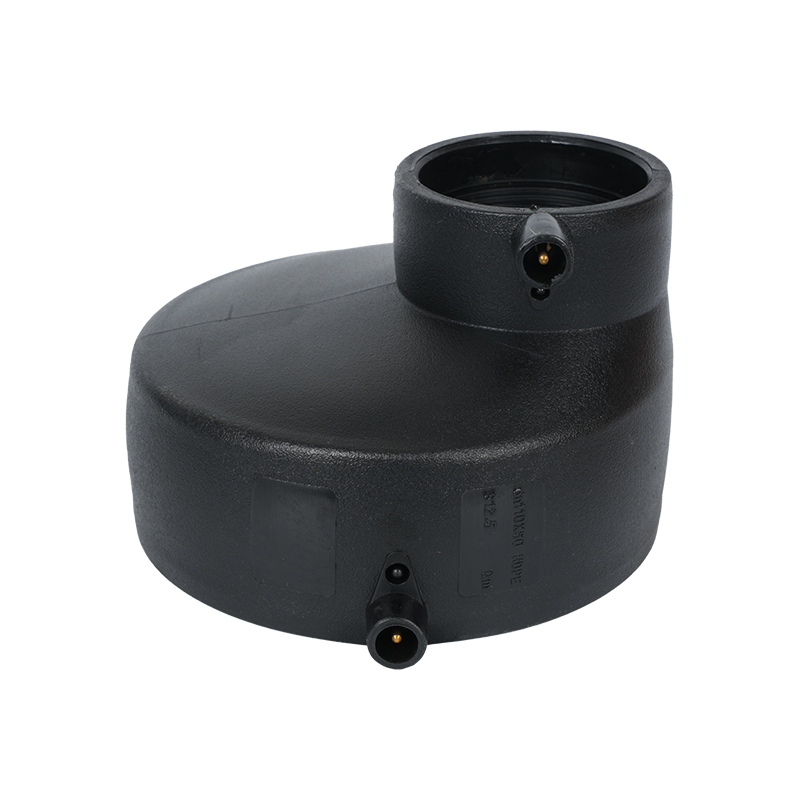

Electrofusion Eccentric Reducer

The Electrofusion Eccentric Reducer is an advanced pipe joining solution designed for plastic and composite piping systems. This product combines the reliability of electrofusion welding technology with the flexibility of eccentric design, bringing many advantages and conveniences to pipeline projects.

Technical Characteristics

This product has better sealing performance and uses electrofusion welding technology to achieve a molecular-level sealing effect, effectively preventing medium leakage and ensuring safe operation of the system. At the same time, precise control of welding parameters can provide high-strength, durable connections that can withstand high pressure and complex working conditions.

The special eccentric structure of Electrofusion Eccentric Reducer gives it unique advantages. It can adjust the flow direction and angle of the pipe without replacing the pipe to adapt to complex installation needs. This greatly improves installation flexibility and convenience.

In addition, the product features easy operation. The installation process is simple and fast, without the need for complex mechanical tools or professional skills, which can greatly shorten the construction period. This saves time and cost for users and improves work efficiency.

Specifications

| SPECIMICATION |

| 75x50 |

| 110x50 |

| 110x75 |

| 160x75 |

| 160x110 |

-

High-density polyethylene (HDPE) pipes are widely recognized for their exceptional corrosion resistance, long service life, and durability. Among HDPE pipe components, the HDPE Butt Fusion Equal Tee p...

READ MORE -

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE

KEEP IN TOUCH