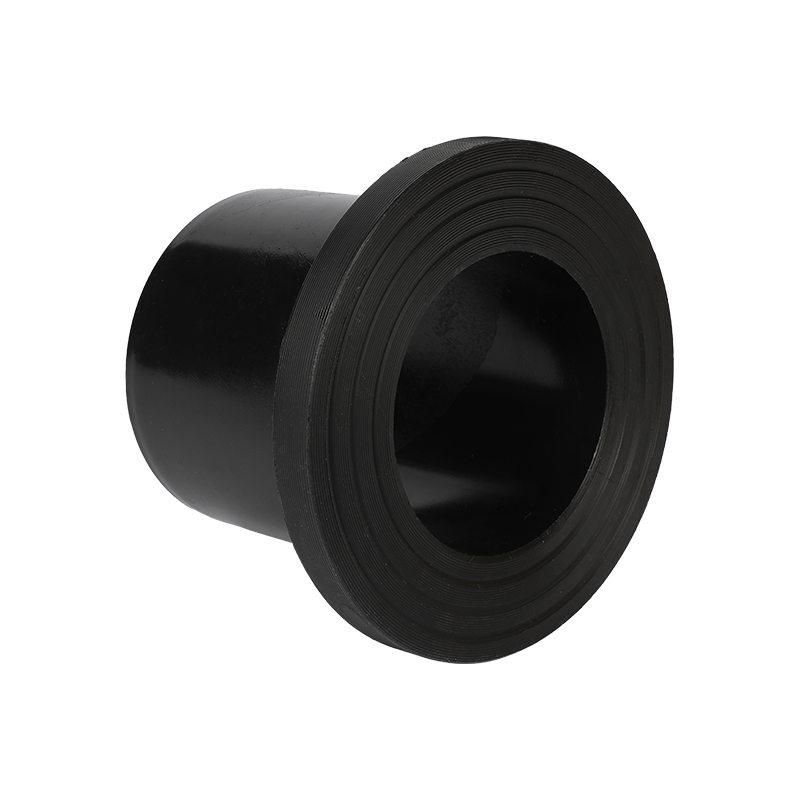

Electrofusion End Cap

As an indispensable connection accessory in plastic pipe systems, electrofusion end caps are widely used in the connection and sealing of polyethylene (PE) pipes. Its core working principle is based on electrofusion welding technology. By heating the electric heating wire at the end of the pipe, the contact surface between the end cap and the pipe is melted, thereby achieving a high-strength sealed connection. This process not only ensures the airtightness of the system, but also improves the pressure resistance, meeting the high requirements of modern pipeline systems for safety and reliability.

The design and manufacture of electrofusion end caps fully consider their application needs in various environments. Its corrosion resistance enables it to be used for a long time in a variety of chemical media, greatly reducing the risk of pipeline damage caused by corrosion. Whether in acidic or alkaline environments or other harsh conditions, electrofusion end caps show excellent durability. In addition, its operating temperature range is -40℃ to 60℃, allowing it to maintain stable performance under extreme climatic conditions. This wide adaptability makes electrofusion end caps an ideal choice for pipeline systems in multiple industries.

Technical Characteristics

Specifications

|

SIZE |

|

50 |

|

63 |

|

75 |

|

90 |

|

110 |

|

160 |

|

200 |

|

250 |

|

315 |

|

400 |

-

High-density polyethylene (HDPE) pipes are widely recognized for their exceptional corrosion resistance, long service life, and durability. Among HDPE pipe components, the HDPE Butt Fusion Equal Tee p...

READ MORE -

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE

KEEP IN TOUCH