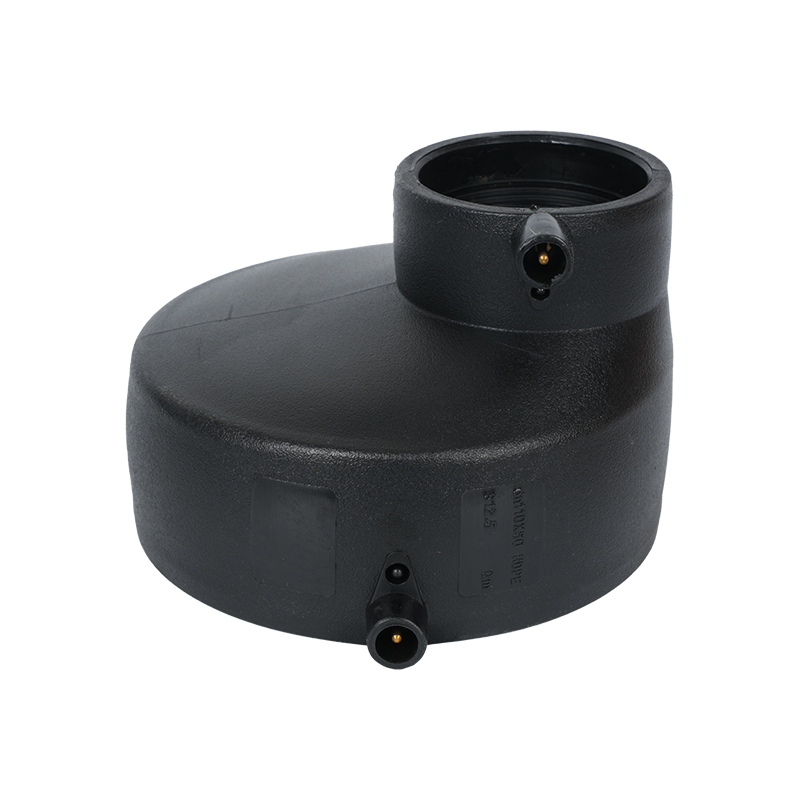

Electrofusion PPR 90° Elbow Fittings

As an important connection component in the pipeline system, Electrofusion PPR 90° Elbow Fittings are widely used in the connection and sealing of polypropylene (PPR) pipes. Its core working principle is to use electric heating technology to make the contact surface of the joint and the pipe reach the required melting temperature, thereby realizing the melting bonding between molecules and forming a stable connection structure. This connection method is increasingly favored by modern pipeline engineering due to its unique advantages.

The significant feature of electrofusion connection is that the connection formed by it has almost no risk of water leakage. This feature makes Electrofusion PPR 90° Elbow Fittings particularly outstanding in application scenarios with extremely high requirements for sealing, such as drinking water supply systems and chemical transportation. Compared with traditional connection methods, electrofusion joints provide a more reliable sealing effect, reduce the risk of leakage caused by loose or aging joints, and greatly improve the overall safety and stability of the system.

PPR materials themselves have excellent corrosion resistance and can effectively resist the erosion of various chemical media. In the process of combining electrofusion joints with PPR pipes, the formed welding points also show excellent corrosion resistance. This feature enables Electrofusion PPR 90° Elbow Fittings to be widely used in many industries such as chemical industry and food processing, ensuring the safety and reliability of pipeline systems in various harsh environments.

Technical Characteristics

Color:

green

Raw Material:

PP-R 100

Type of Welding:

Electrofusion

Application Fields:

– Drinking water distribution;

– Systems for hot and cold water distribution;

– HVAC systems;

– High temperature heating;

– District heating systems;

– Industrial fluids transportation;

– Reverse osmosis (RO) systems;

– Compressed air systems;

– Chemical transport;

– Shipbuilding.

Specifications

-

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building drainage systems. Their corrosion resistance, lightweight nature, high strength, and long service life make them ideal for rainwater, w...

READ MORE -

HDPE (High-Density Polyethylene) threaded fittings are widely used in water supply, drainage, gas, and chemical industries due to their excellent corrosion resistance, wear resistance, and toughness. ...

READ MORE

KEEP IN TOUCH