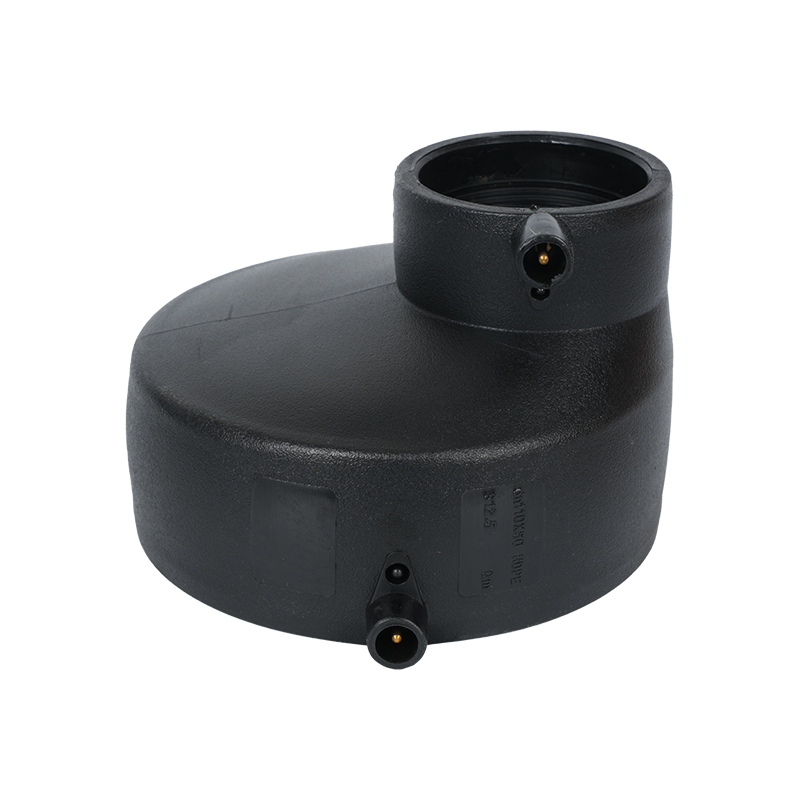

HDPE Ball Branch

HDPE Ball Branch is an environmentally friendly and durable engineering plastic product made of high-quality high-density polyethylene (HDPE) material and has many unique characteristics. It effectively resists various chemicals and environmental erosion, maintaining its integrity even under conditions, thereby extending the service life of the pipeline. This makes it in applications such as wastewater treatment, chemical plants, and oil and gas transmission that require resistance to highly corrosive environments.

Technical Characteristics

HDPE Ball Branch has better compressive strength, can withstand large working pressure, and meets various high-pressure transportation needs. At the same time, its non-permeable properties ensure the sealing performance of liquids and gases, reducing the risk of leakage and improving energy efficiency.

The spherical design of HDPE Ball Branch helps to evenly distribute pressure and reduce stress concentration, thus enhancing the stability of the pipeline. In addition, the spherical structure is easy to install and maintain, saving construction time and costs. Its smooth surface makes it less likely to breed bacteria and algae, helping to keep the inside of the pipe clean, which is an important hygienic advantage for drinking water supply systems or the food industry. In addition, because HDPE has better insulation properties, it can effectively prevent heat loss and save energy.

Specifications

| SPECIFICATION |

| 110 |

-

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building drainage systems. Their corrosion resistance, lightweight nature, high strength, and long service life make them ideal for rainwater, w...

READ MORE

KEEP IN TOUCH