HDPE Electrofusion 90 Degree Elbow

HDPE electrofusion 90 degree elbow, as an efficient and reliable pipe connection component, plays an indispensable role in the modern engineering field. This product is made of high-density polyethylene (HDPE) material and has corrosion resistance, wear resistance and long-term stability. It is widely used in many fields such as water supply and drainage, gas transportation, agricultural irrigation and so on.

Technical Characteristics

Zhejiang Fengfeng pipe industry HDPE (High-Density Polyethylene) electrofusion 90-degree elbow is a type of fitting used in pipeline systems, particularly for gas, water, and other fluid transportation. This fitting allows for the connection of two HDPE pipes at a 90-degree angle, forming a right-angle bend in the pipeline.

The electrofusion process is used to join these fittings to the HDPE pipes by using an electrofusion coil built into the fitting. When electrical current is applied, the coil heats up, causing the HDPE material to melt slightly and fuse together with the pipes, forming a strong, permanent bond.

Key features of an HDPE electrofusion 90-degree elbow:

Durability: HDPE is resistant to chemicals, corrosion, and UV degradation, making it ideal for outdoor and underground applications.

Leak-free connections: The electrofusion process creates a reliable, leak-proof joint.

Easy installation: Compared to traditional welding or flanged joints, electrofusion fittings are easier and quicker to install.

Wide temperature range: HDPE can function within a broad temperature range, making it suitable for various environments.

Applications include:

Water supply and distribution systems

Gas pipelines

Wastewater systems

Industrial fluid transport

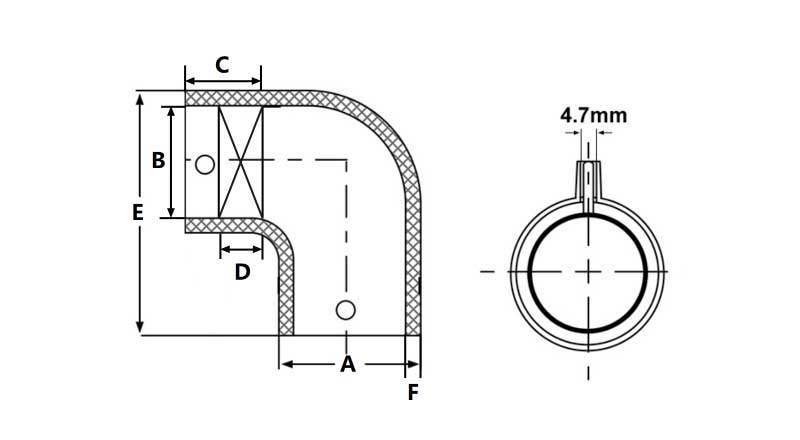

Specifications

| SDR11 | ||||||

| SPECIFICATION | SIZE(mm) | |||||

| A | B | C | D | E | F | |

| 50 | 59 | 50 | 50 | 27 | 4.5 | |

| 63 | 74.4 | 63 | 53 | 27 | 5.7 | |

| 75 | 86.6 | 75 | 60 | 29 | 6.8 | |

| 90 | 106 | 90 | 67 | 32 | 8.1 | |

| 110 | 130 | 110 | 73 | 35 | 10 | |

| 125 | 147 | 125 | 74 | 40 | 11.3 | |

| 160 | 189 | 160 | 87 | 47 | 14.5 | |

| 200 | 236 | 200 | 93 | 50 | 22.7 | |

| 225 | 266 | 225 | 105 | 50 | 20.5 | |

| 250 | 295 | 250 | 105 | 51 | 22.7 | |

| 315 | 372 | 315 | 140 | 67 | 28.6 | |

| SDR17 | ||||||

| SPECIFICATION | SIZE(mm) | |||||

| A | B | C | D | E | F | |

| 315 | 352 | 315 | 120 | 60 | 18.5 | |

| 400 | 447 | 400 | 145 | 75 | 23.5 | |

| 500 | 558 | 500 | 150 | 90 | 29 | |

| 630 | 690 | 630 | 190 | 110 | 30 | |

-

High-density polyethylene (HDPE) pipes are widely recognized for their exceptional corrosion resistance, long service life, and durability. Among HDPE pipe components, the HDPE Butt Fusion Equal Tee p...

READ MORE -

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE

KEEP IN TOUCH