HDPE Electrofusion Reducing Tee

HDPE Electrofusion Reducing Tee uses electric hot melt connection to achieve permanent connection between pipes without using any mechanical connectors or seals. This connection method is not only easy and fast to operate, but also has stable and reliable connection quality, effectively eliminating the risk of pipeline leakage. HDPE Electrofusion Reducing Tee has good pressure resistance and can withstand large pressures, ensuring the stable operation of the pipeline system. At the same time, its corrosion resistance is also very good and can resist the erosion of various chemical substances, effectively extending the service life of the product.

Technical Characteristics

In terms of structural design, this product adopts a reasonable diameter reduction design to achieve a smooth transition between pipes of different diameters. At the same time, the inner wall of the product is smooth and the water flow resistance is small, effectively ensuring the smooth flow of the pipeline system. In addition, its compact structural design also saves installation space and makes the pipeline layout more reasonable and beautiful.

In practical applications, HDPE Electrofusion Reducing Tee is widely used in water supply, drainage, gas, heating and other pipeline systems. It can be seen in urban water supply projects, drainage projects, industrial parks, agricultural irrigation and other fields. With its better performance, stable quality and convenient installation method, it provides safe and reliable connection solutions for various pipeline systems.

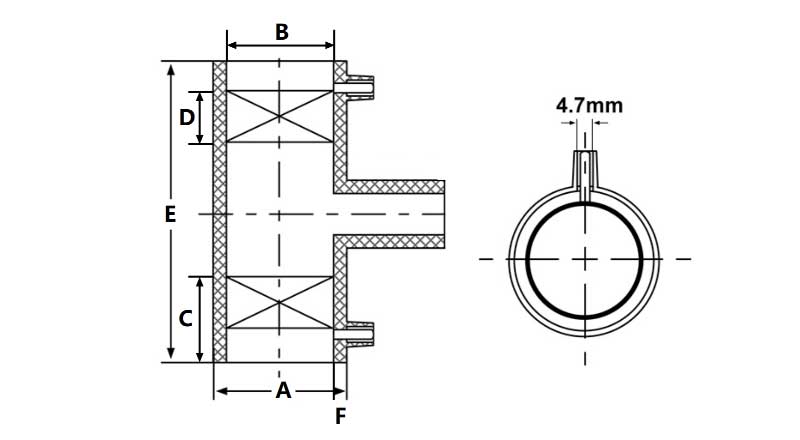

Specifications

| SDR11 | ||||||

| SPECIFICATION | SIZE(mm) | |||||

| A | B | C | D | E | F | |

| 50x40 | 59 | 50 | 50 | 25 | 142 | 4.5 |

| 63x50 | 74.4 | 63 | 50 | 27 | 162 | 5.7 |

| 75x50 | 88.6 | 75 | 58 | 29 | 180 | 6.8 |

| 75x63 | 88.6 | 75 | 58 | 29 | 180 | 6.8 |

| 90x80 | 106 | 90 | 64 | 32 | 205 | 8.1 |

| 90x63 | 106 | 90 | 64 | 32 | 205 | 8.1 |

| 90x75 | 106 | 90 | 64 | 32 | 205 | 8.1 |

| 110x50 | 130 | 110 | 70 | 35 | 235 | 10 |

| 110x63 | 130 | 110 | 70 | 35 | 235 | 10 |

| 110x75 | 130 | 110 | 72 | 35 | 235 | 10 |

| 110x90 | 130 | 110 | 72 | 35 | 235 | 10 |

| 125x75 | 147 | 125 | 70 | 37 | 255 | 11.36 |

| 125x90 | 147 | 125 | 70 | 37 | 255 | 11.36 |

| 125x110 | 147 | 125 | 70 | 37 | 255 | 11.36 |

| 160x50 | 189 | 160 | 77 | 47 | 295 | 14.5 |

| 160x63 | 189 | 160 | 77 | 47 | 295 | 14.5 |

| 160x75 | 189 | 160 | 77 | 47 | 295 | 14.5 |

| 160x90 | 189 | 160 | 77 | 47 | 295 | 14.5 |

| 160x110 | 189 | 160 | 77 | 47 | 295 | 14.5 |

| 160x125 | 189 | 160 | 77 | 47 | 295 | 14.5 |

| 200x50 | 236 | 200 | 100 | 50 | 290 | 18.1 |

| 200x63 | 236 | 200 | 100 | 50 | 290 | 18.1 |

| 200x75 | 236 | 200 | 100 | 50 | 290 | 18.1 |

| 200x90 | 236 | 200 | 100 | 50 | 290 | 18.1 |

| 200x110 | 236 | 200 | 100 | 50 | 290 | 18.1 |

| 200x125 | 236 | 200 | 100 | 50 | 360 | 18.1 |

| 200x160 | 236 | 200 | 100 | 50 | 360 | 18.1 |

| 225x110 | 266 | 225 | 100 | 55 | 370 | 20.4 |

| 225x160 | 266 | 225 | 100 | 55 | 370 | 20.4 |

| 225x200 | 266 | 225 | 100 | 55 | 370 | 20.4 |

| 250x110 | 298 | 250 | 110 | 51 | 430 | 22.7 |

| 250x160 | 298 | 250 | 110 | 51 | 430 | 22.7 |

| 250x200 | 298 | 250 | 110 | 51 | 430 | 22.7 |

| 315x90 | 372 | 315 | 135 | 67 | 535 | 28.6 |

| 315x110 | 372 | 315 | 135 | 67 | 535 | 28.6 |

| 315x160 | 372 | 315 | 135 | 67 | 535 | 28.6 |

| 315x200 | 372 | 315 | 135 | 67 | 535 | 28.6 |

| 315x250 | 372 | 315 | 135 | 67 | 535 | 28.6 |

| SDR17 | ||||||

| SPECIFICATION | SIZE(mm) | |||||

| A | B | C | D | E | F | |

| 315x110 | 352 | 315 | 120 | 60 | 500 | 18.5 |

| 315x160 | 352 | 315 | 120 | 60 | 500 | 18.5 |

| 315x200 | 352 | 315 | 120 | 60 | 500 | 18.5 |

| 315x250 | 352 | 315 | 120 | 60 | 500 | 18.5 |

| 400x110 | 447 | 400 | 150 | 75 | 630 | 23.5 |

| 400x160 | 447 | 400 | 150 | 75 | 630 | 23.5 |

| 400x200 | 447 | 400 | 150 | 75 | 630 | 23.5 |

| 400x250 | 447 | 400 | 150 | 75 | 630 | 23.5 |

| 400x315 | 447 | 400 | 150 | 75 | 630 | 23.5 |

| 500x110 | 558 | 500 | 150 | 90 | 725 | 29 |

| 500x160 | 558 | 500 | 150 | 90 | 725 | 29 |

| 500x200 | 558 | 500 | 150 | 90 | 725 | 29 |

| 500x250 | 558 | 500 | 150 | 90 | 725 | 29 |

| 500x315 | 558 | 500 | 150 | 90 | 725 | 29 |

| 500x400 | 558 | 500 | 150 | 90 | 725 | 29 |

-

High-density polyethylene (HDPE) pipes are widely recognized for their exceptional corrosion resistance, long service life, and durability. Among HDPE pipe components, the HDPE Butt Fusion Equal Tee p...

READ MORE -

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE

KEEP IN TOUCH