HDPE Floating Wave Breakwater

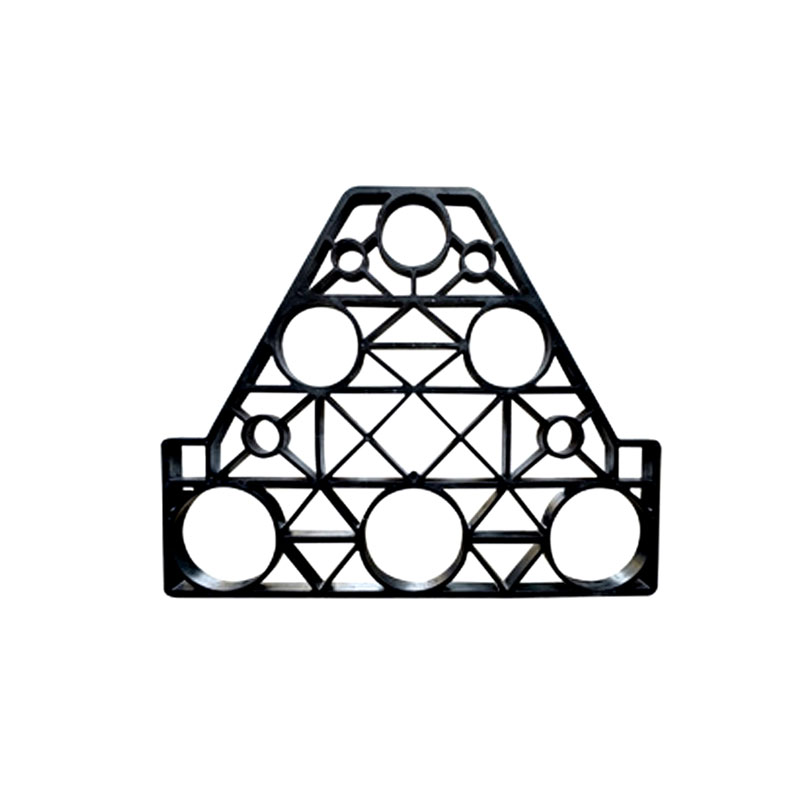

HDPE breakwater bracket, characterized by its cost-effectiveness, serves as a floating barrier to deflect waves and currents, ensuring the safety of

aquaculture facilities.

Its applications extend to safeguarding critical coastlines, protecting coastal tourism infrastructure (including beaches), preserving leisure and sightseeing fishing spots, and providing defense for offshore drilling platforms and military installations, Additionally, it offers temporary shelter at offshore construction sites, thereby increasing operational capacity, reducing construction timelines, and optimizing project outcomes.

System Advantages:

Using brand new food-grade HDPE material as production raw materials. Environmentally friendly and safe, with high material strength, flexibility, impact resistance, and good corrosion resistance.

HDPE material is lightweight and has the characteristics of easy movement and good construction convenience.

With the right technical support, it can withstand frontal assaults from Seale 12 Typhoon, demonstrating robust resistance to wind and waves.

Technical Characteristics

Specifications

Box body: The production of l set of marine aquaculture cages is equivalent to that of 100 traditional eages.

Frame:

Made of HDPE synthetic material, characterized by high strength, corrosion resistance, and strong wind and wave resistance.

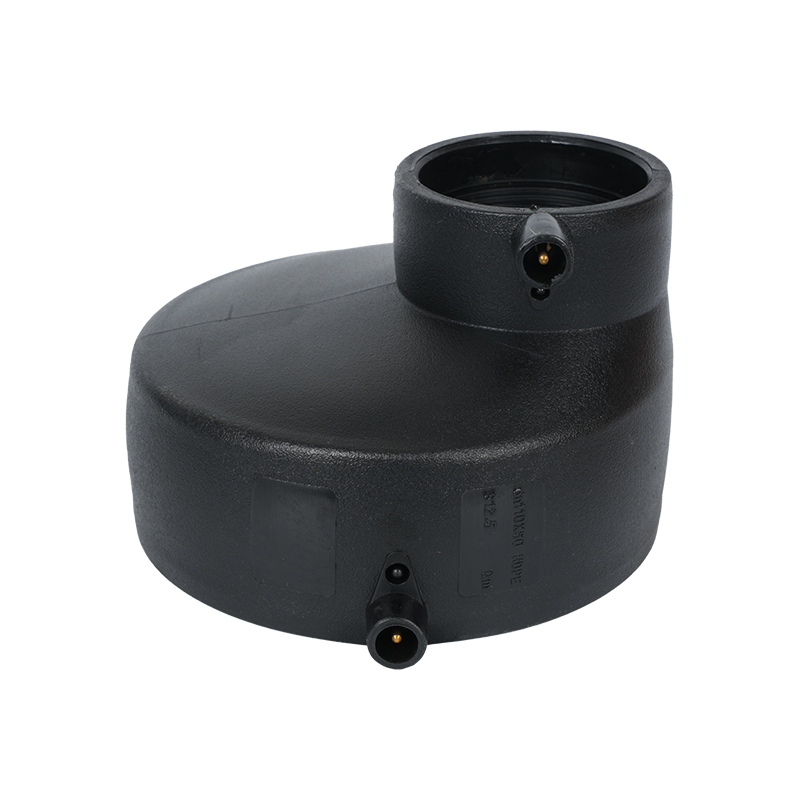

Buoyancy device: HDPE solid-wall hollow pipes

Scope of Application: Open waters from 15m to 50m deep

Seakeeping: Excellent resilience, strong seakeeping ability

Durability: Safely usable for 4-5 years

Environmental protection property: HDPE material, no pollutants produced, recyclable

Safety: Equipped with safety guardrails for protection

Application property: Able to be customized in size

Economic efficiency: Superior durability with lower costs

Efficiency: Large-scale aquaculture, fast fish production, high product quality

-

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building drainage systems. Their corrosion resistance, lightweight nature, high strength, and long service life make them ideal for rainwater, w...

READ MORE

KEEP IN TOUCH