HDPE Butt Fusion End Cap

HDPE Butt Fusion End Cap is a high-quality high-density polyethylene (HDPE) hot melt end cap product designed to provide a reliable solution for end sealing of pipe systems. It uses advanced Butt Fusion (butt hot melt) technology to seamlessly connect with HDPE pipes to ensure a long-lasting and durable sealing effect.

Technical Characteristics

The biggest feature of this product is its better sealing performance. Through hot-melt docking technology, the head and the pipeline are perfectly integrated to form a uniform and dense connection layer, which effectively prevents the leakage of liquid or gas and ensures the safe operation of the pipeline system. In addition, the hot-melt part of the product is designed using a special process to ensure the flatness and strength of the connection, reduce stress concentration, and extend the service life.

In terms of materials, HDPE Butt Fusion End Cap has better performance. HDPE material has better corrosion resistance and anti-aging properties and can be used for a long time in harsh environments without being easily damaged. At the same time, the material also has high strength and toughness and can withstand large pressure and impact forces, ensuring the stable operation of the pipeline system.

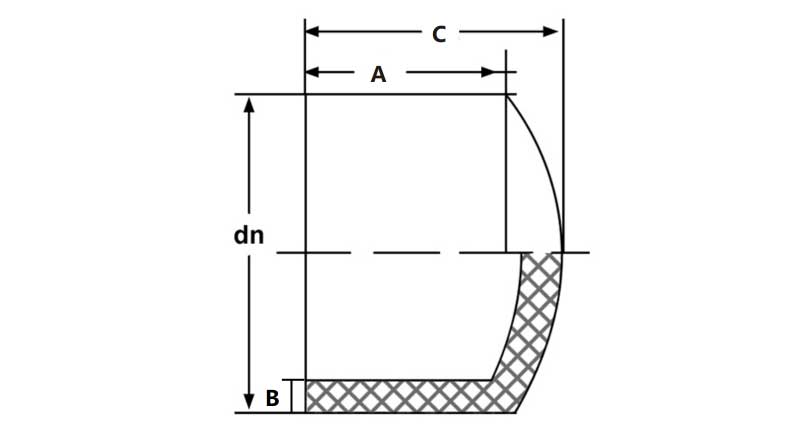

Specifications

| dn | Size(mm) | Thickness | ||||

| SPECIFICATION (dn) |

A | B | C | SDR17 | SDR13.6 | SDR11 |

| 75 | 57 | 7 | √ | |||

| 90 | 62 | 8.3 | √ | |||

| 110 | 62 | 10.4 | √ | √ | ||

| 125 | 63 | 12.3 | √ | √ | ||

| 140 | 66 | 13.3 | √ | √ | ||

| 160 | 70 | 15 | √ | √ | ||

-

High-density polyethylene (HDPE) pipes are widely recognized for their exceptional corrosion resistance, long service life, and durability. Among HDPE pipe components, the HDPE Butt Fusion Equal Tee p...

READ MORE -

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE

KEEP IN TOUCH