What preparations should be made before installing HDPE socket fusion fitting

2024.12.02

2024.12.02

Industry news

Industry news

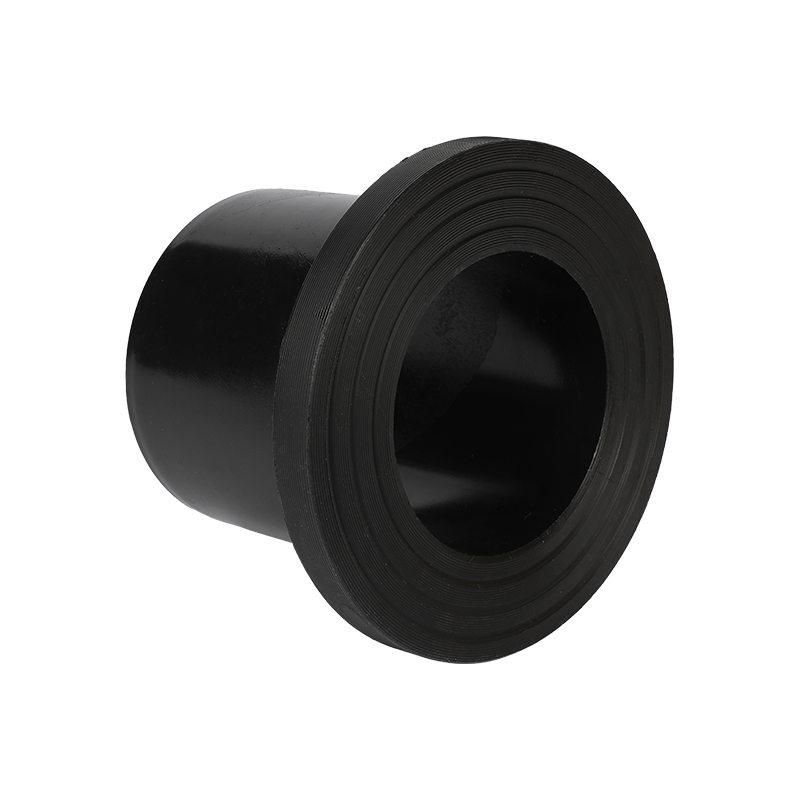

HDPE (high-density polyethylene) electric hot-melt socket joints play a vital role in the pipeline system. The preparation work before its installation is the key link to ensure the safe, stable and long-term operation of the entire pipeline system. The following is a professional preparation guide for the installation of hdpe socket fusion fitting.

Design plan and material preparation

Before installing the HDPE pipeline system, a detailed design plan must be made first. The plan should be based on engineering requirements and actual needs, and reasonably plan key parameters such as the direction of the pipeline, the location of the connection points, and the selection of pipe diameters. During the design process, the terrain, geological conditions and environmental factors must be fully considered, and possible maintenance needs in the future must be foreseen to ensure the rationality and practicality of the pipeline system.

In terms of material preparation, HDPE pipes and related accessories that meet engineering standards should be selected, including electric hot-melt joints, flanges, valves, etc. All materials must undergo strict quality inspection to ensure that they have qualified certificates and meet national or industry standards. For pipeline systems for special environments or purposes, HDPE materials and accessories with corresponding characteristics should be selected to meet specific needs.

Tool and equipment preparation

The preparation of construction tools is also crucial. Commonly used construction tools include pipe cutters, hot-melt welders, and flange connection tools. All tools and equipment must be in good condition to ensure the smooth progress of the construction process. In particular, the electric hot melt welding machine should be debugged and calibrated in advance to ensure that parameters such as heating temperature and time meet the requirements of the product manual, so as to ensure the quality of welding.

Worksite preparation

Cleaning the construction area is an important step to ensure construction safety. Debris and obstacles in the construction area should be removed to ensure the cleanliness and flatness of the construction environment. At the same time, necessary enclosures and warning signs should be set up to ensure the safety of construction workers.

When marking the direction of the pipeline, the direction and connection point of the pipeline should be accurately marked in the construction area according to the design plan. Use auxiliary equipment such as marking pens and measuring tools to ensure the accuracy of the calibration to avoid errors in subsequent construction.

Personnel training and safety protection

Professional training of construction personnel is the basis for ensuring construction quality and safety. The training content should cover the installation process, operating specifications and safety precautions of the HDPE pipe system. In addition, construction personnel should be equipped with necessary safety protection supplies, such as safety helmets, protective glasses and gloves, to ensure that each construction worker can work in a safe environment.

Construction workers need to understand and comply with relevant safety operating procedures to reduce risks during construction and ensure construction safety.

Other preparations

Before installation, the pipes and joints must be carefully inspected to ensure that they are free of damage, cracks, and foreign matter. The end faces of the pipes should be kept flat and the joints should be intact.

During the cleaning and drying process, use special detergents or alcohol to thoroughly clean the connecting surfaces of the pipes and joints. Avoid using detergents containing corrosive substances to avoid damaging the pipes or joints.

Finally, the control of ambient temperature and humidity should not be ignored. During the installation process, pay close attention to environmental conditions and avoid construction in extreme weather, such as high temperature, low temperature, or strong winds. If construction is required at night, be sure to provide sufficient lighting equipment to ensure the safety and effectiveness of construction.

KEEP IN TOUCH