What maintenance measures should be taken for HDPE Socket Fusion Fitting after installation?

2024.12.09

2024.12.09

Industry news

Industry news

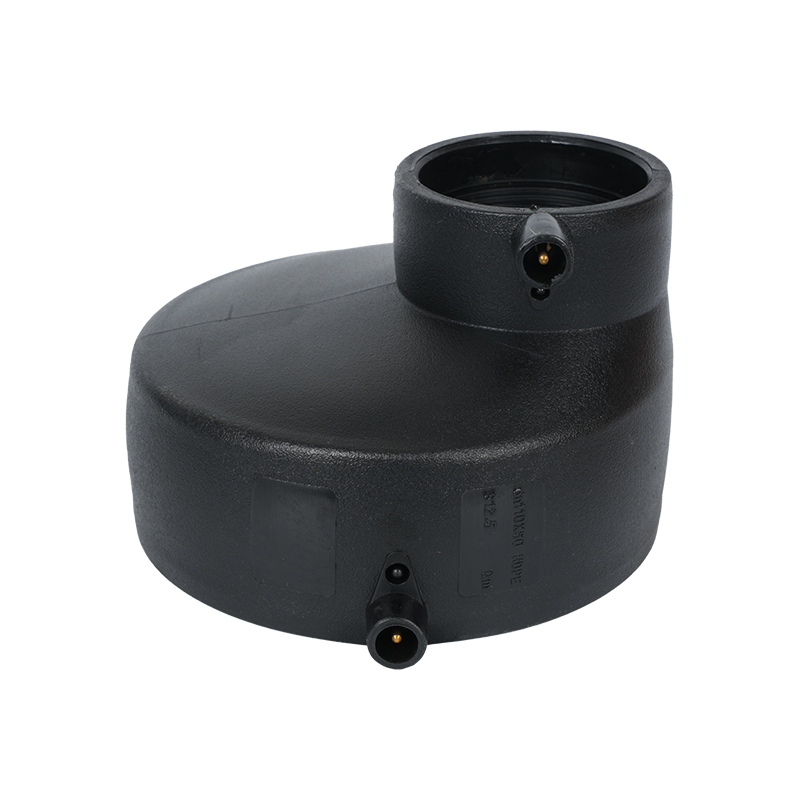

As a key connection element in the pipeline system, the performance and maintenance of HDPE (high-density polyethylene) electric hot-melt socket fittings directly affect the stability and safety of the entire pipeline system. Therefore, regular inspection, cleaning and maintenance, troubleshooting and environmental safety factors of HDPE Socket Fusion Fitting are particularly important.

In terms of regular inspection and evaluation, appearance inspection is the basic link. A comprehensive appearance evaluation of HDPE Socket Fusion Fitting should be carried out regularly, focusing on whether there are cracks, deformation, corrosion or foreign matter adhesion on the surface of the joint. At the same time, it is necessary to check the status of fasteners at the connection, including bolts and nuts, to ensure that they are firmly connected to avoid leakage or failure caused by looseness.

Sealing evaluation is an important link to ensure the safe operation of the pipeline system. The sealing performance of the joint can be effectively evaluated by implementing methods such as pressure testing and leak detection. Once a leak is found, repair or replacement measures should be taken immediately to prevent potential safety hazards. Performance monitoring includes continuous tracking of pipeline system operating parameters, such as pressure, flow and temperature, to ensure that these parameters are always within the normal range. If any abnormality is found, the cause should be quickly investigated, and the HDPE Socket Fusion Fitting should be checked for damage.

In terms of cleaning and maintenance, it is necessary to regularly clean the dirt and impurities in the HDPE Socket Fusion Fitting and its surrounding environment to avoid corrosion or reduced sealing due to dirt accumulation. Appropriate cleaning agents and tools should be selected to avoid damaging the joints with corrosive materials. In addition, regular lubrication of the joints can effectively reduce friction and wear, thereby extending their service life. For joints that are exposed to harsh environments for a long time, additional protective measures, such as spraying anti-corrosion coatings, are recommended to enhance their durability.

In the troubleshooting and repair process, when a pipeline system fails, the status of the HDPE Socket Fusion Fitting should be checked first, including whether it is damaged or loose. The use of professional testing equipment, such as ultrasonic detectors and infrared thermal imagers, can improve the accuracy of troubleshooting. Problems found, such as loose joints, poor sealing or corrosion, should be repaired immediately. During the repair process, it is important to follow relevant operating procedures and safety regulations to ensure the quality of the repair and the safety of the operation.

KEEP IN TOUCH