How to Choose Suitable HDPE Siphon Drainage Fittings to Suit Complex Terrain

2024.08.22

2024.08.22

Industry news

Industry news

1. Understand the characteristics of the terrain

When selecting HDPE Siphon Drainage Fittings to adapt to complex terrain, the first task is to deeply understand and analyze the specific characteristics of the terrain. This includes the slope changes, elevation differences, soil type distribution, groundwater level, and possible natural or man-made obstacles. Through detailed site surveys and terrain mapping, accurate terrain data can be obtained to provide a scientific basis for subsequent pipeline design and material selection. For terrain with steep slopes or large elevation differences, special attention should be paid to the stability and safety of the drainage system, and HDPE Siphon Drainage Fittings that can withstand greater water pressure and impact should be selected.

2. Determine drainage requirements

Drainage requirements are one of the key factors in selecting HDPE Siphon Drainage Fittings. According to the terrain characteristics and drainage requirements, the required drainage volume, flow rate, and design parameters of the pipeline system need to be accurately calculated. These parameters will directly affect the specifications, models, and quantity of HDPE Siphon Drainage Fittings. In complex terrain, drainage requirements may vary from region to region, and multiple factors such as rainfall intensity, catchment area, and water flow rate need to be considered comprehensively. Through scientific calculation and analysis, it can be ensured that the selected HDPE Siphon Drainage Fittings can meet the actual drainage needs and ensure the smooth operation of the drainage system.

3. Choose the right HDPE material

HDPE material is an ideal choice for Siphon Drainage Fittings due to its excellent chemical stability, corrosion resistance and wear resistance. However, when selecting HDPE materials, it is also necessary to pay attention to its specific performance indicators and quality assurance. Different brands and models of HDPE materials may have differences in density, strength, toughness, etc., and these differences will directly affect the use effect and life of HDPE Siphon Drainage Fittings. Therefore, when choosing, brands with a good reputation and reliable quality certification should be given priority. By consulting relevant standards and specifications, ensure that the selected HDPE material meets the engineering requirements and has sufficient corrosion resistance and wear resistance to meet the challenges brought by complex terrain and harsh environment.

4. Consider the type of pipe fittings and connection methods

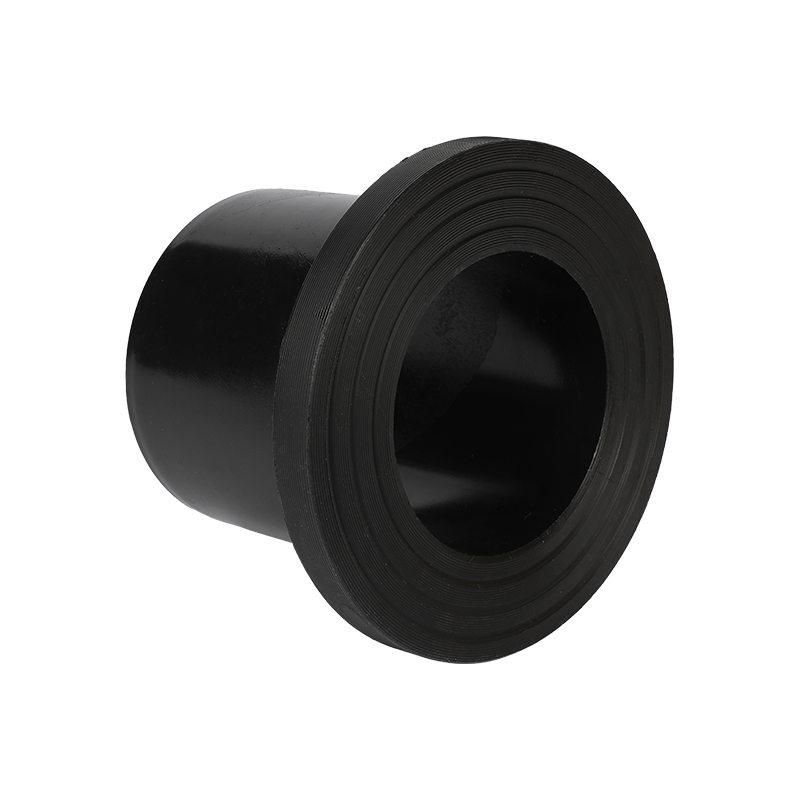

HDPE Siphon Drainage Fittings have a variety of types and connection methods to choose from, each of which has its unique advantages and scope of application. In complex terrain, the overall layout of the pipeline system, construction conditions, and post-maintenance factors should be comprehensively considered to select the most suitable pipe fittings and connection methods. As one of the high-performance pipe fittings widely used in modern pipeline systems, electrofusion joints have the advantages of high connection strength, good sealing performance, and convenient construction. They have been widely used in HDPE Siphon Drainage Fittings. However, when selecting electrofusion joints, attention should also be paid to issues such as its matching with pipeline materials, the requirements of connection processes, and the adaptability to the construction environment. In addition, other types of pipe fittings and connection methods, such as hot melt joints and mechanical joints, should also be considered so that they can be flexibly selected and used in combination under specific circumstances.

5. Consider construction conditions and convenience

Complex terrain often brings certain challenges and difficulties to construction. When selecting HDPE Siphon Drainage Fittings, full consideration should be given to construction conditions and convenience. First, it should be ensured that the selected pipe fittings are easy to transport and carry to the construction site to reduce transportation costs and construction difficulties. Secondly, attention should be paid to the installation method and construction requirements of the pipe fittings, and the type of pipe fittings that are easy to install and disassemble should be selected to improve construction efficiency and quality. In addition, environmental factors at the construction site, such as temperature, humidity, wind speed, etc., need to be considered to ensure safety and stability during construction. In complex terrain, special construction techniques and equipment may be required to assist in the installation of HDPE Siphon Drainage Fittings, such as using an excavator to dig trenches and using a crane to hoist pipe fittings. Therefore, when selecting pipe fittings, their construction convenience and compatibility with construction techniques must also be considered.

KEEP IN TOUCH