Buttfusion Welding Machine

Buttfusion welding machine is a device with advanced welding technology. It adopts a fully automated process without filling materials. It only needs to butt two pieces of metal to achieve seamless fusion between molecules through the heat generated by high-frequency current. This welding method not only saves time and materials, but also significantly improves welding quality and reduces the risk of welding defects such as blowholes and cracks.

Technical Characteristics

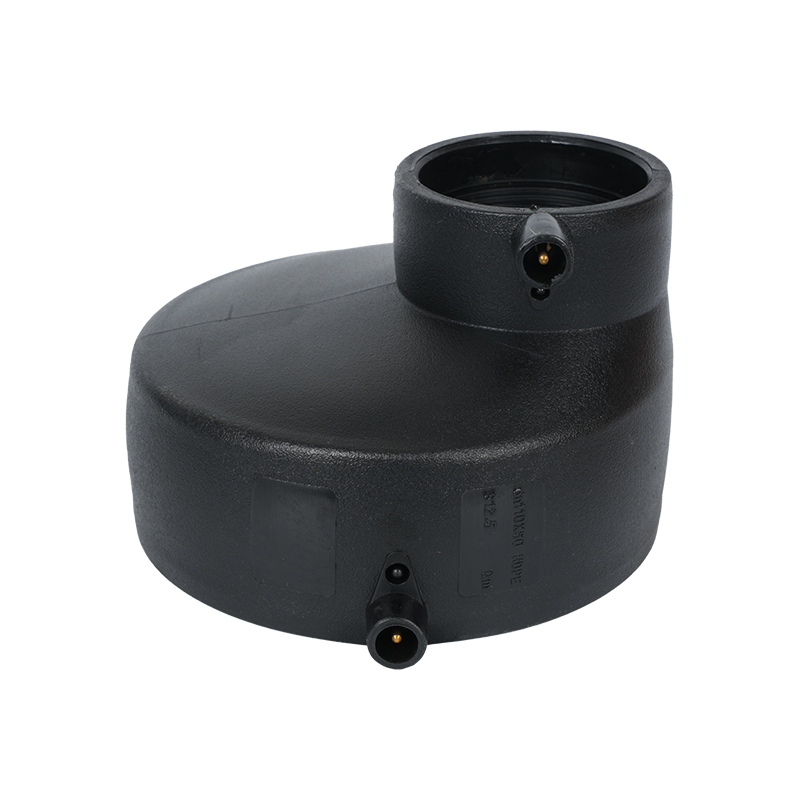

The equipment is equipped with an advanced induction heating system that can accurately control the temperature to ensure uniform heating of the welding points, thereby ensuring the strength and durability of the welds. The core feature of the Buttfusion welding machine is its unique welding technology, which uses the heat generated by high-frequency current to maximize the bonding strength between metal material molecules, thereby achieving a stronger welding effect. This welding method is suitable for various materials, such as PE, PP, PVC, etc., and has a wide range of applications.

Specifications

-

High-density polyethylene (HDPE) pipes are widely recognized for their exceptional corrosion resistance, long service life, and durability. Among HDPE pipe components, the HDPE Butt Fusion Equal Tee p...

READ MORE -

High-density polyethylene (HDPE) pipes are widely used in water supply, gas distribution, wastewater, and chemical transport systems due to their excellent corrosion resistance, durability, and long s...

READ MORE -

HDPE siphon drainage fittings are widely used in modern building rainwater, wastewater, and industrial drainage systems due to their corrosion resistance, lightweight nature, high strength, and ease o...

READ MORE

KEEP IN TOUCH