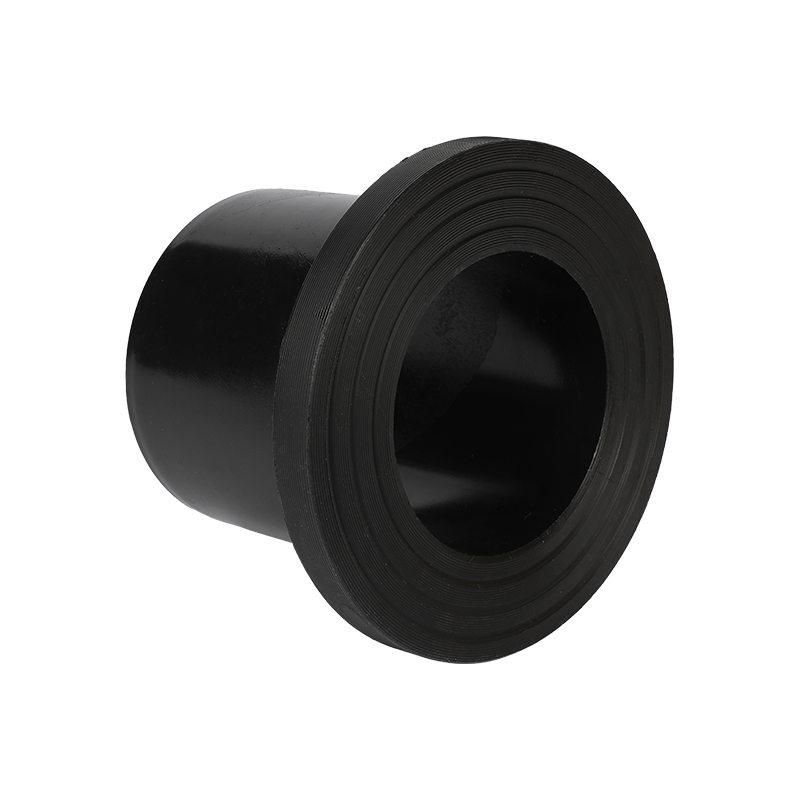

HDPE Socket Fusion Reducing Coupler

HDPE Socket Fusion Reducing Coupler is an accessory specially designed for HDPE (high-density polyethylene) pipes. Its main function is to reduce friction during the pipe connection process, thereby improving the reliability and stability of the connection. The product is made of high-quality materials and has the characteristics of corrosion resistance, high temperature resistance and wear resistance. The surface has been specially treated to have better corrosion resistance and chemical resistance, ensuring the long-term reliability of the product.

Technical Characteristics

The main advantages of HDPE Socket Fusion Reducing Coupler are its better performance and premium quality. First, it can greatly improve the reliability of the connection. By reducing friction when connecting pipes, this accessory can ensure the firmness and stability of the connection and effectively avoid connection problems caused by pipe movement or rotation. At the same time, it can also improve the stability of the connection. Friction is one of the biggest challenges in the connection process. Using HDPE Socket Fusion Reducing Coupler can effectively reduce friction, thereby improving the stability of the connection and ensuring that the pipes will not twist or rotate during connection.

In addition, HDPE Socket Fusion Reducing Coupler can effectively reduce leakage. Reducing the friction of pipes during connection can reduce the incidence of leakage and ensure the sealing and stability of pipe connections. In practical applications, this product has been widely used and recognized. It can be applied to various pipeline systems, including water supply, drainage, chemical industry, oil, natural gas and other fields.

Specifications

| SPECIFICATION | |

| 25x20 | 75x40 |

| 32x20 | 75x50 |

| 3 2x25 | 75x63 |

| 40x20 | 90x25 |

| 40x25 | 90x32 |

| 40x32 | 90x40 |

| 50x20 | 90x50 |

| 50x25 | 90x63 |

| 50x32 | 90x75 |

| 50x40 | 110x32 |

| 63x20 | 110x40 |

| 63x25 | 110x50 |

| 63x32 | 110x63 |

| 63x40 | 110x75 |

| 63x50 | 110x90 |

| 75x20 | |

| 75x25 | |

| 75x32 | |

-

HDPE Welding Fundamentals HDPE (High-Density Polyethylene) is highly regarded in industrial fields primarily because it is an excellent thermoplastic material. This means that when heated to its melti...

READ MORE -

Understanding HDPE Fusion: Why Heat Matters In HDPE (High-Density Polyethylene) piping systems, welding is more than just a connection; it is the realignment of molecular chains through thermal energy...

READ MORE -

Technical Analysis: Compatibility Between PVC Fittings and HDPE Piping In piping engineering, using PVC solvent-cement fittings directly on HDPE pipe is strictly prohibited. This is due to fundamental...

READ MORE

KEEP IN TOUCH