What should be paid attention to when welding HDPE socket fusion fitting

2025.01.06

2025.01.06

Industry news

Industry news

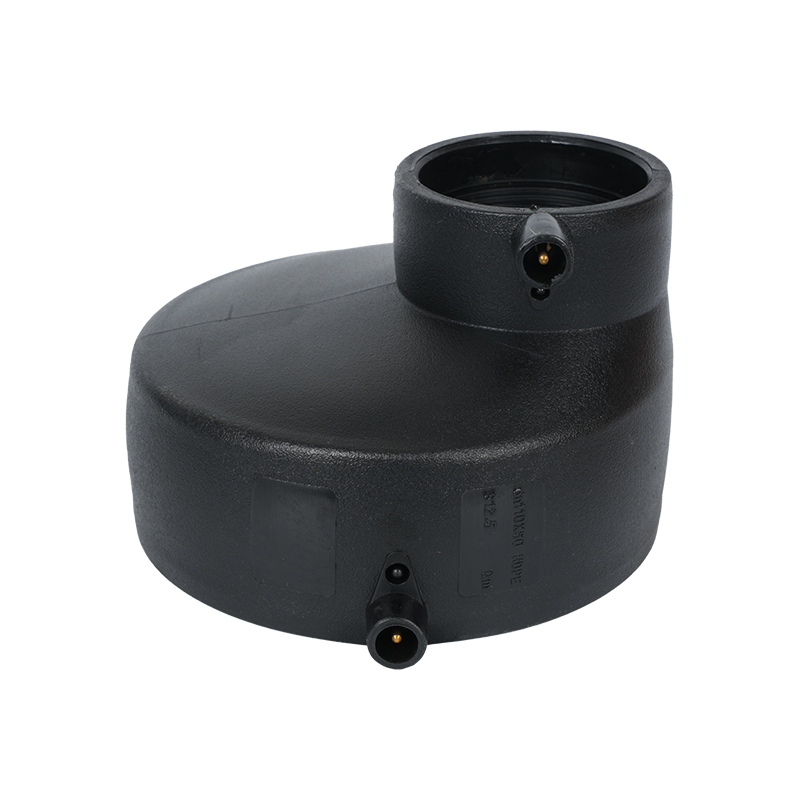

In modern pipeline construction, welding technology is widely used in the connection of high-density polyethylene (HDPE) pipes. To ensure the quality of welding, pre-construction preparation, key steps of welding operation and safety and environmental protection measures are essential.

Preparation before welding

Material inspection

Before the welding operation begins, the HDPE pipe and its socket welding pipe fittings must be fully inspected. The inspection includes confirming that there are no defects such as cracks, scratches, deformation, etc. on the surface of the material, and ensuring that its surface is clean, free of oil and dust. Although the pipe fittings provided by Zhejiang Fengfeng Pipe Industry have undergone strict quality inspection, secondary inspection on site should not be ignored to ensure that the materials meet the construction standards.

Tools and equipment

The tools and equipment required for welding include heating plates, scrapers, clamps and presses, etc., which must be ensured to be intact and functioning properly. The temperature of the heating plate should be set according to the specifications of the pipes and fittings and the manufacturer's recommendations, usually controlled between 200-230℃ to ensure temperature stability during the welding process.

Environmental preparation

The welding operation should be carried out in a dry, clean and well-ventilated environment to avoid the influence of rain, dust and other pollutants on the welding quality. At the same time, the temperature at the construction site should be kept within an appropriate range to prevent excessively high or low temperatures from adversely affecting the welding effect.

Key steps and precautions for welding operation

Preparation of pipes and fittings

Before welding, use a scraper to remove the oxide layer on the inner wall of the pipe and fitting socket and the insertion end to ensure that the fresh material surface is exposed. This process is critical to the quality of welding, because the presence of the oxide layer will significantly affect the fusion effect of the material.

Heating and welding

Place the heating plate on the contact surface of the pipe and fitting, heat it to the specified temperature and keep it for a period of time to soften the material. The heating time needs to be precisely controlled according to the specifications of the pipe and fitting and the temperature of the heating plate. After heating, quickly remove the heating plate and immediately insert the pipe into the socket of the fitting, while applying appropriate pressure to ensure that the two fit tightly.

Pressure and cooling

During the welding process, the pressure applied should be uniform and moderate to avoid deformation of the pipe fitting due to excessive pressure or weak welding due to too little pressure. After welding is completed, a certain pressure must be maintained until the material is completely cooled and solidified. The cooling time should be reasonably determined according to the specifications of the pipes and fittings and the ambient temperature to ensure the stability of the connection.

Inspection of welding quality

After the welding is completed, the connection parts need to be carefully inspected to ensure that the welding is uniform and free of defects such as bubbles, cracks or slag inclusions. If necessary, non-destructive testing methods such as ultrasonic testing and X-ray testing can be used for further quality assessment to ensure the reliability of the connection.

Safety and environmental protection precautions in welding operations

Personal protection

During the welding operation, construction personnel should wear appropriate personal protective equipment, such as safety helmets, protective glasses and gloves, to prevent injuries caused by high temperature or accidents.

Fire prevention measures

Since the heating plate will generate high temperature when working, the construction site must have perfect fire prevention measures to prevent the occurrence of fire and ensure construction safety.

Environmental protection requirements

During the welding process, the waste and smoke generated should be properly handled to avoid pollution to the environment. Zhejiang Fengfeng Pipe Industry advocates green construction and encourages customers to adopt environmentally friendly waste disposal solutions to achieve sustainable development goals.

KEEP IN TOUCH